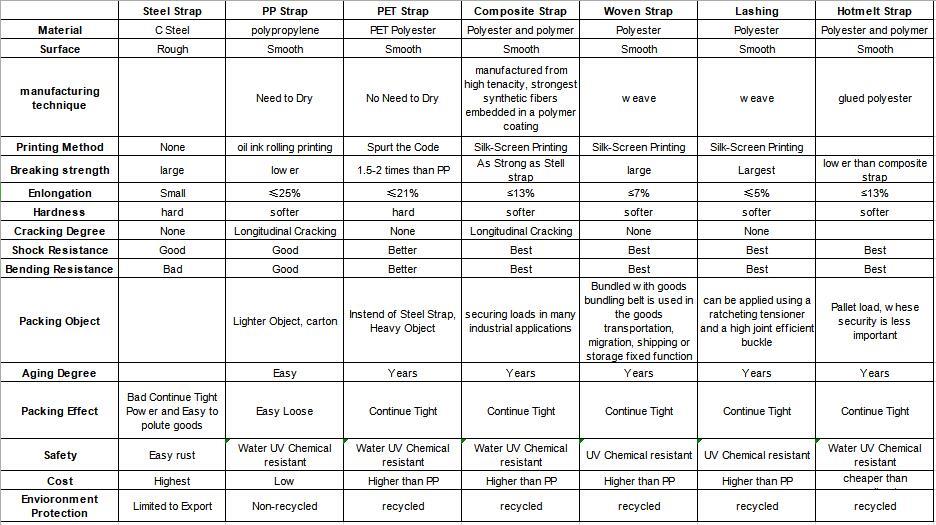

Plastic strapping includes: composite cord strapping, hot melt cord strapping, pp strapping, PET strapping. different material and manufacturing technique will be different properties and applications.

Steel strapping: the breaking strength is good but the face is rough and not easy to strapping, the enlongation is too small ,it is easy rust cause to instantaneous fracture, the bending resistance is bad,.Bad continue tight power and easy to polute goods.

High hardness and hard to produce, easy to occur bur, rough surface and easy to hurt finger, not very convinient for packing.

PP strapping: The breaking strength is too small, the enlongation is close to 25%, it easy loose after strapping, it is easy rust with simple strapping buckleeasy aging and non-recycled.

It is just used for packing carton and lighter objects.

PET strapping: The breaking strength is 1.5-2 times than PP strapping, the enlongation is close to 21%, the hardness is hard and not easy to strapping, it is easy rust with simple strapping buckle.

it is just used for packing lighter objects.

Composite cord strapping and hot melt cord strapping: It is composited by high tanacity polyester yarn and PP glue, the breaking strength is the same as the steel strapping, it is stronger than PP strapping and PET strapping, the enlongation is less than 13% and easy to contionue tight, foft and yearrs aging, the shock resistance and bending resistance is the best. it is easier and safer than steel strapping, PP strapping, PET strapping.

securing loads in many industrial applications, such as steel tube, steel reinforcement, pallate, chemical, alumimum ingot, motor, wood, Cartons, Mining and Resources, Oil and Gas, Storage,Transportation, securing loads in many industrial

- Previous: composite Cord Strapping For Pallet

- Next: Industrial Strapping

Related News

- Useful Life Of Composite Strapping

- A Guide To Cargo Strapping

- Everything You Have To Know About The Strapping

- The Maintenance Of Lashing Straps

- Benefits Of Composite Strapping

- Advantages Of Using Polyester Composite Strapping

- What Is Composite Strapping?

- Do You Know Polyester Strapping?

- Polyester Flat Webbing Sling With Soft Eye Protection

- Woven Vs. Composite Strap

- Polyester Strapping Vs Steel Strapping

- Polyester Lashing Strap Was Containerized And Ready To Be Ship To Germany

- Metal Serrated Seals

- Cord Strap And Buckle